OD / ID AIR GAUGING

AIR GAGING: Air gaging is one of Edmunds' core measurement technologies. We have developed a two-master, back-pressure bleed system which is the most accurate air gaging method to use. Specific information about the history of air gaging, how it works, the various systems, and our wide range of tooling may be found in our catalog which you can download or view right now from this page. You can also link to particular air gaging product pages or an air gage ordering worksheet. Please Contact us for additional information.

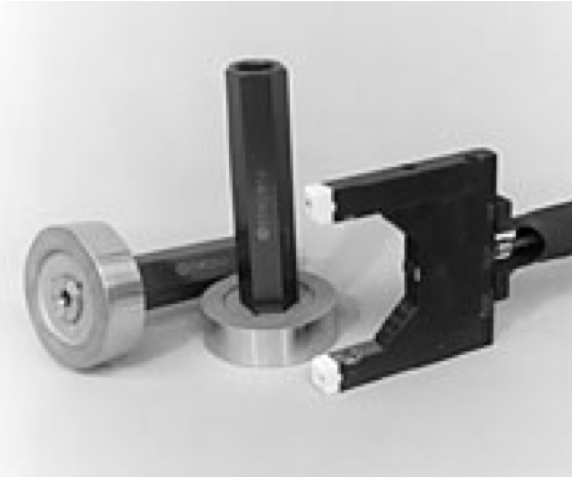

AIR PLUG: Edmunds Air Plugs are designed for back-pressure bleed, back-pressure, flow and differential systems. Styles are available for deep hole, shallow hole, thru-hole, blind-hole and close-to-shoulder applications. Sizes range from .120 inches (3.05mm) to and including 6.010 inches (152.65mm). Our leaf contact design, in sizes ranging from .573 inches (14.55mm) to 6.010 inches (152.65mm), is ideal for parts with inconsistent surface finishes.

AIR RINGS :Edmunds Air Snap tooling is custom designed for difficult to reach or between centers diameter measurements. They may be designed to gage a part while it is engaged in the machine tool. Edmunds Air Snaps feature durable tungsten carbide rest pads for long wear, and a lightweight aluminum handle. They may be designed for use with all air gaging systems, and are available with up to three circuits. A vee-type backstop may also be specified.To request complete specifications and information on Edmunds

AIR SNAPS: Edmunds Air Snap tooling is custom designed for difficult to reach or between centers diameter measurements. They may be designed to gage a part while it is engaged in the machine tool. Edmunds Air Snaps feature durable tungsten carbide rest pads for long wear, and a lightweight aluminum handle. They may be designed for use with all air gaging systems, and are available with up to three circuits. A vee-type backstop may also be specified. To request complete specifications and information on Edmunds