Sealed linear encoders are protected from dust, chips and splash fluids and are ideal for operation on machine tools.

Exposed linear encoders operate with no mechanical contact between the scanning head and the scale or scale tape. Typical areas of application for these encoders include measuring machines, comparators and other precision devices in linear metrology, as well as production and measuring equipment, for example in the semiconductor industry.

With incremental linear encoders,the current position is determined by starting at a datum and counting measuring steps, or by subdividing and counting signal periods. Incremental encoders from HEIDENHAIN feature reference marks, which must be scanned after switch-on to reestablish the datum. This process is especially simple and fast with distance-coded reference marks.

Absolute linear encoders require no previous traverse to provide the current position value. The encoder transmits the absolute value through the EnDat interface or another serial interface.

Sealed linear encoders from HEIDENHAIN are protected from dust, chips and splash fluids and are ideal for operation on machine tools.

- Accuracy grades as fine as ± 2 μm

- Measuring steps as fine as 0.001 μm

- Measuring lengths up to 30 m (to 72 m upon request)

- Fast and simple installation

- Large mounting tolerances

- High acceleration loading

- Protection against contamination

Sealed linear encoders are available with

- Full-size scale housing

– For high vibration loading

– Up to 30 m measuring length - Slimline scale housing

– For limited installation space

– Up to 1 240 mm measuring length, up to 2 040 mm with mounting spar or tensioning elements

The aluminum housing of a HEIDENHAIN sealed linear encoder protects the scale, scanning carriage, and its guideway from chips, dust, and fluids. Downward-oriented elastic lips seal the housing. The scanning carriage travels along the scale on a low friction guide. It is connected to the external mounting block by a coupling that compensates unavoidable misalignment between the scale and the machine guideways.

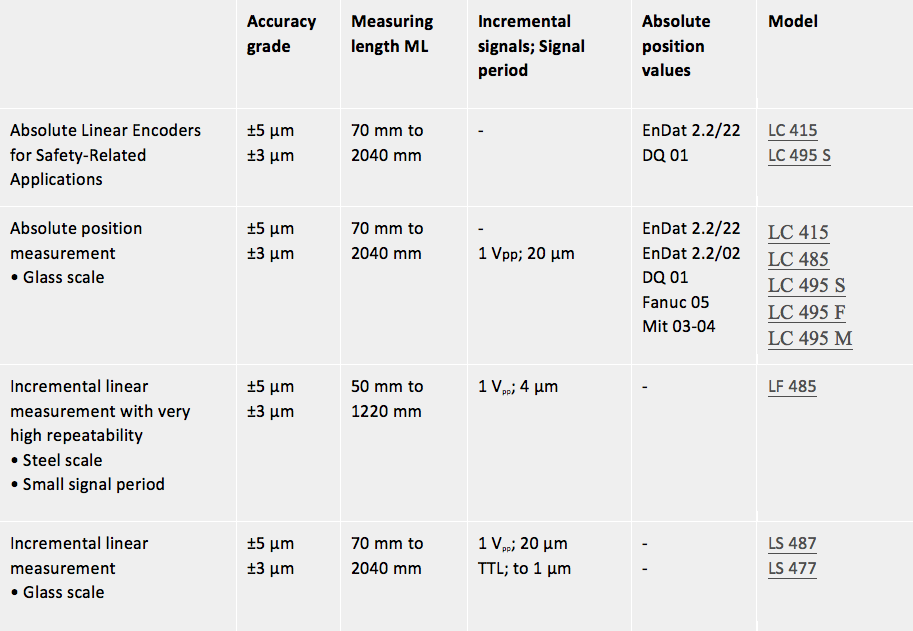

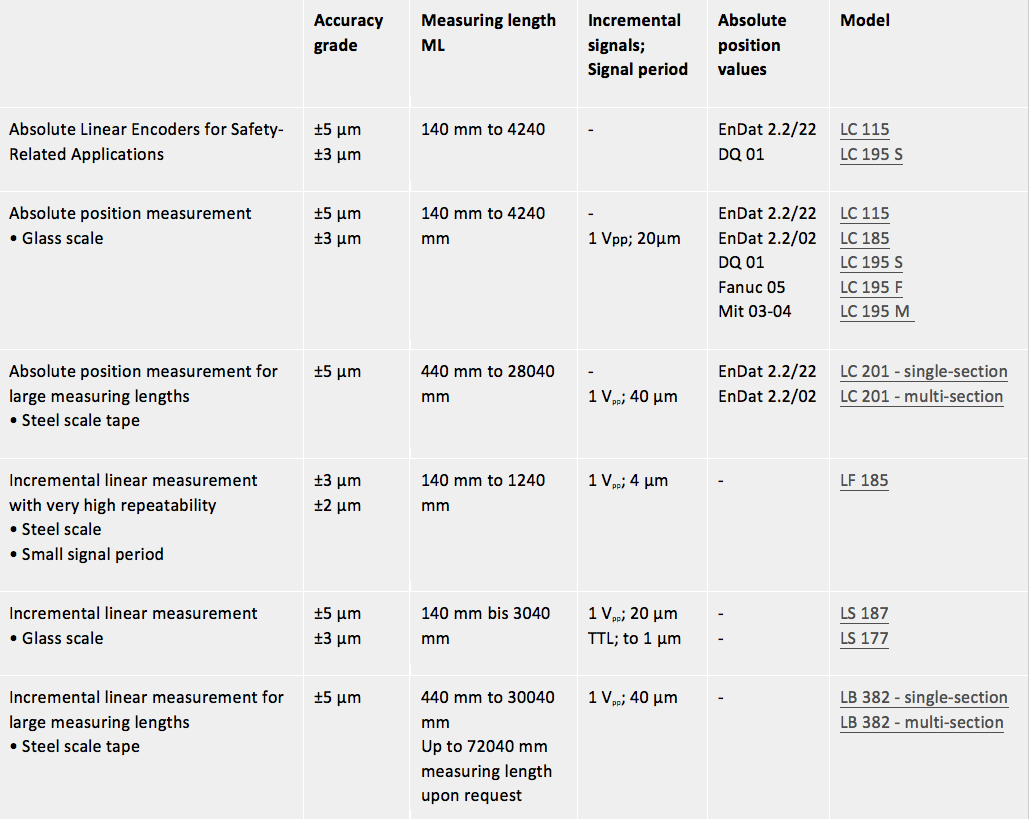

Linear encoders for numerically controlled machine tools

Linear encoders from HEIDENHAIN for numerically controlled machine tools can be used nearly everywhere. They are ideal for machines and other equipment whose feed axes are in a servo loop, such as milling machines, machining centers, boring machines, lathes and grinding machines. The beneficial dynamic behavior of the linear encoders, their high permissible traversing speed, and their acceleration in the direction of measurement predestine them for use on highly-dynamic conventional axes as well as on direct drives.

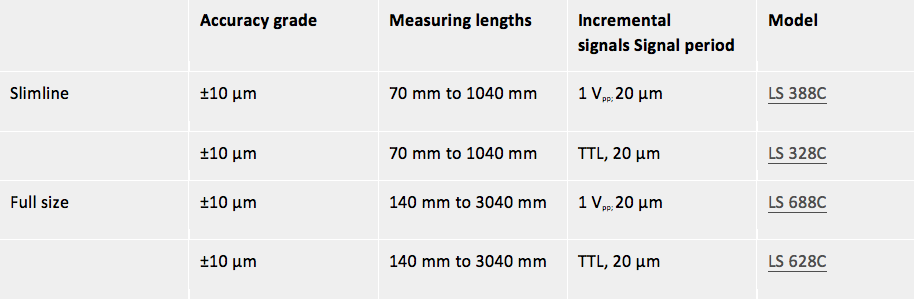

Linear encoders with slimline scale housing

The linear encoders with slimline scale housing are designed for limited installation space. Larger measuring lengths and higher acceleration loads are made possible by using mounting spars or clamping elements.

Linear encoders with full-size scale housing

The linear encoders with full-size scale housing are characterized by their sturdy construction, high resistance to vibration and large measuring lengths. The scanning carriage is connected with the mounting block over an oblique blade that permits mounting both in upright and reclining positions with the same protection rating.

Linear encoders for manually operated machine tools

For typical applications on manual machine tools such as milling machines or lathes, display steps of 10 µm or 5 µm are sufficient. Such display steps are provided by the LS 300 and LS 600 series linear encoders with an accuracy grade of ± 10 µm per meter traverse.

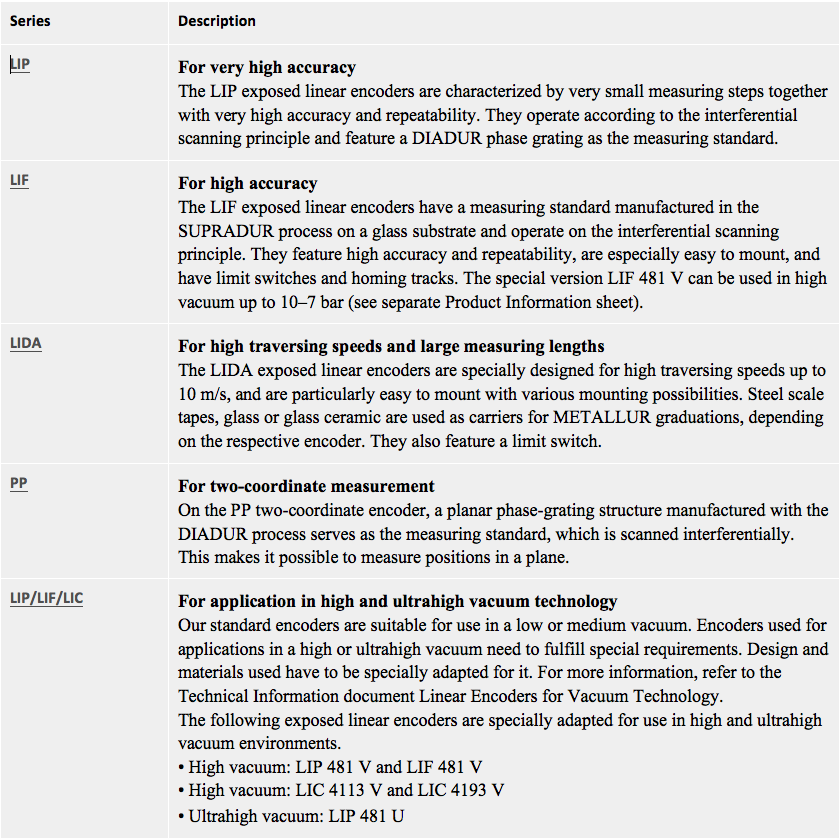

Exposed linear encoders are designed for use on machines and installations that require high accuracy of the measured value. Typical applications include:

- Measuring and production equipment in the semiconductor industry

- PCB assembly machines

- Ultra-precision machines

- High-accuracy machine tools

- Measuring machines and comparators, measuring microscopes, and other precision measuring devices

- Direct drives

Absolute Encoders

Encoders with position value output

Incremental Encoders